Whether you are managing inventory for your business or keeping track of supplies for personal use, having a material quantity record sheet can be incredibly helpful. This tool allows you to easily monitor the quantity of various materials, whether it’s office supplies, raw materials for production, or items in your pantry.

In this comprehensive guide, we will explore the importance of a material quantity record sheet, how to create one, and provide tips for successful implementation.

What is a Material Quantity Record Sheet?

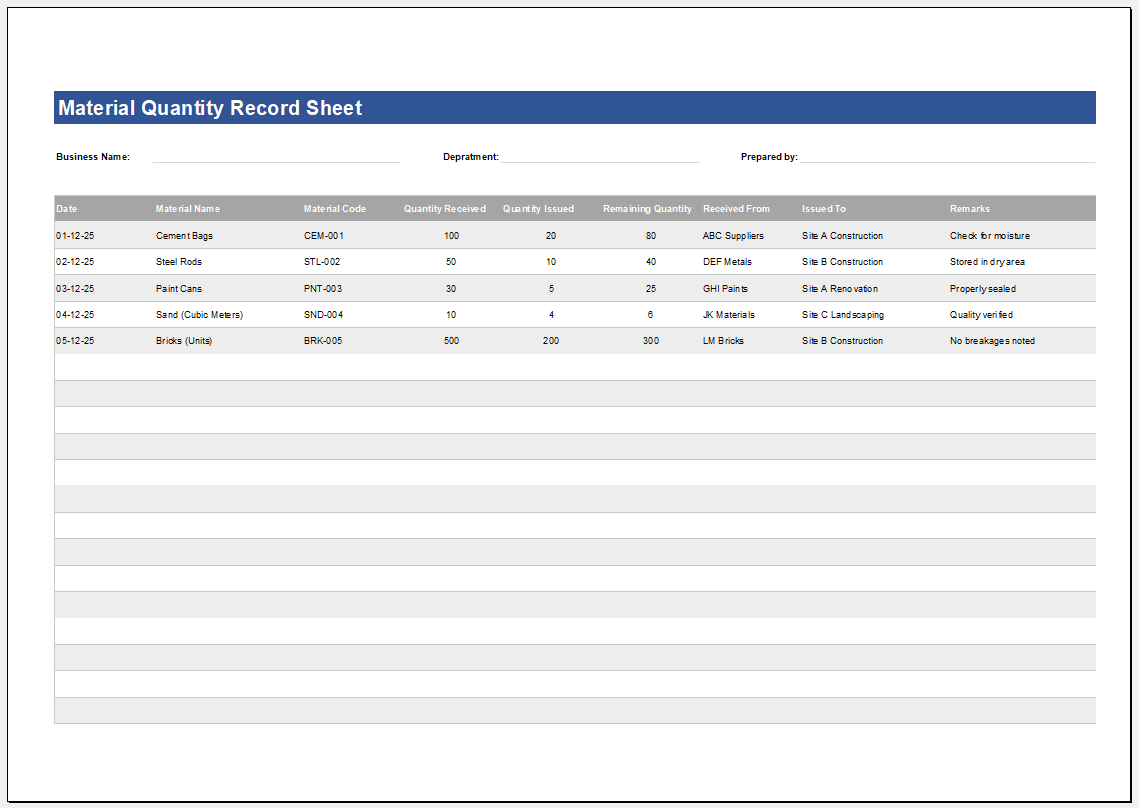

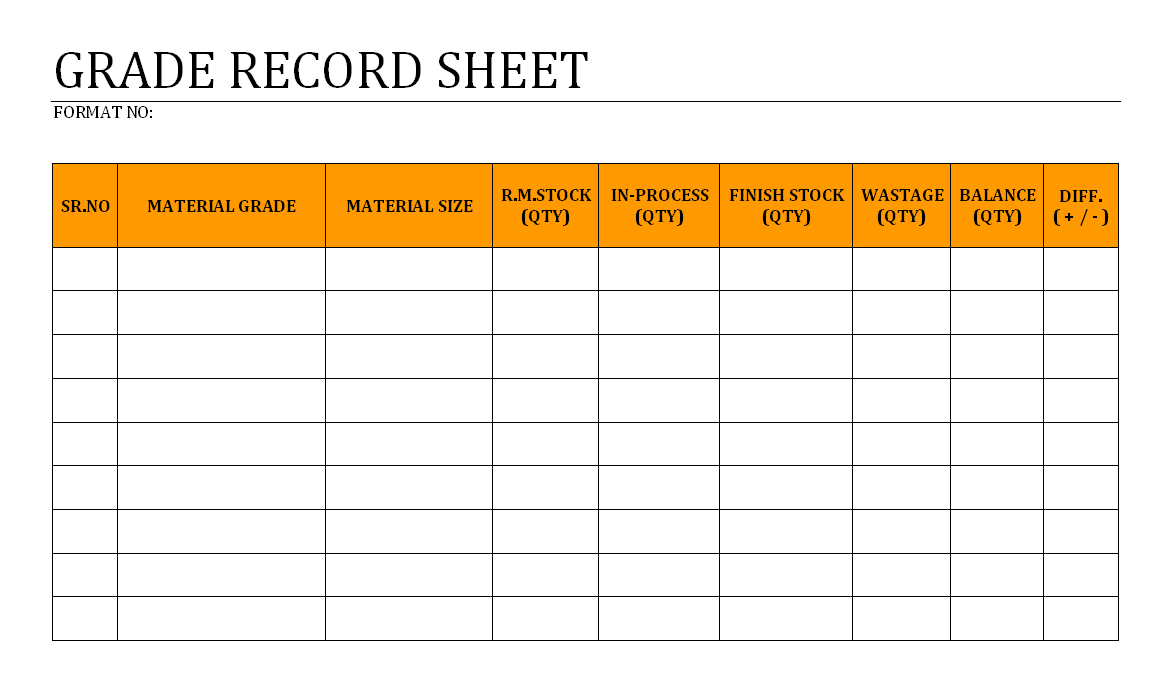

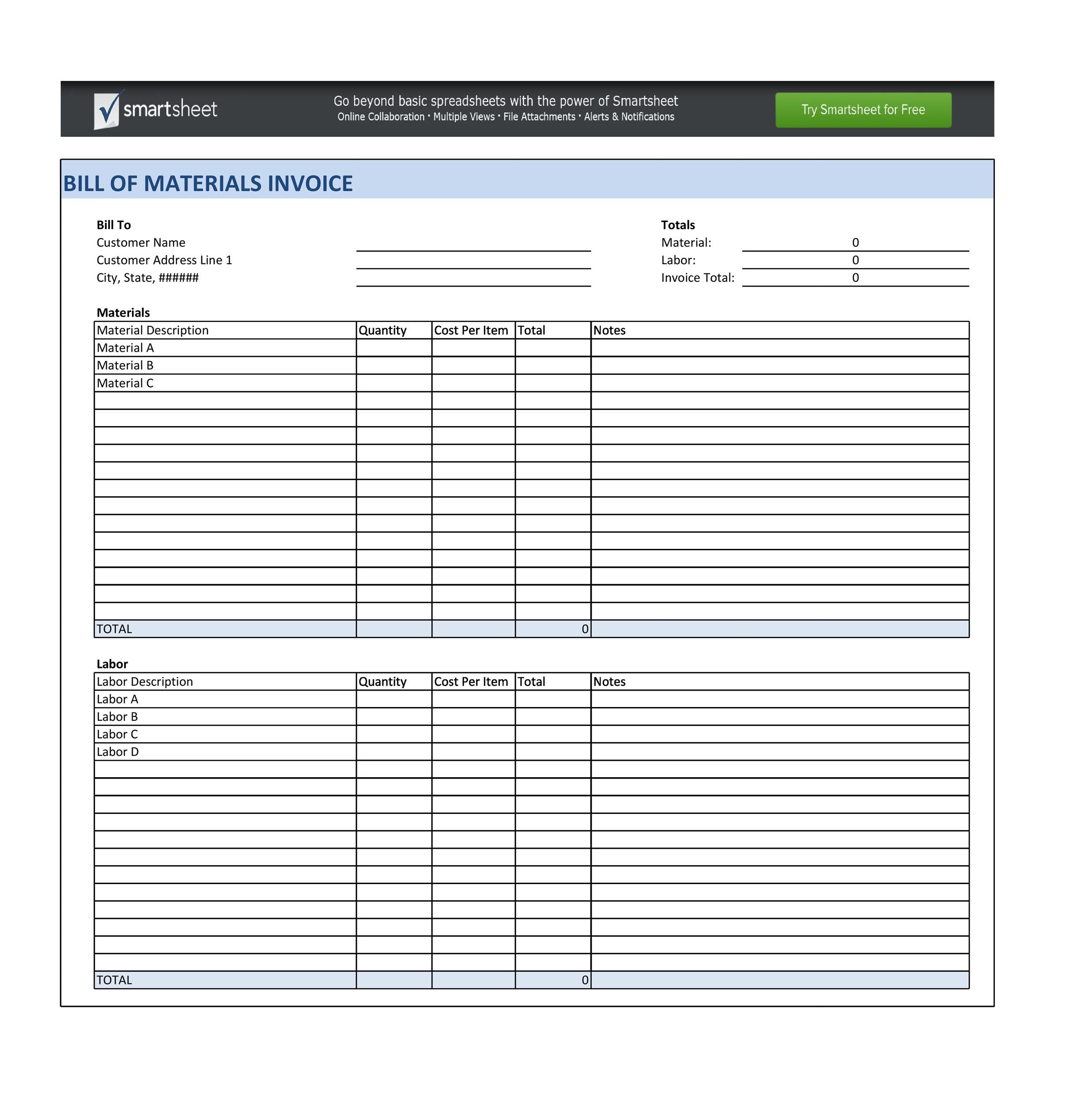

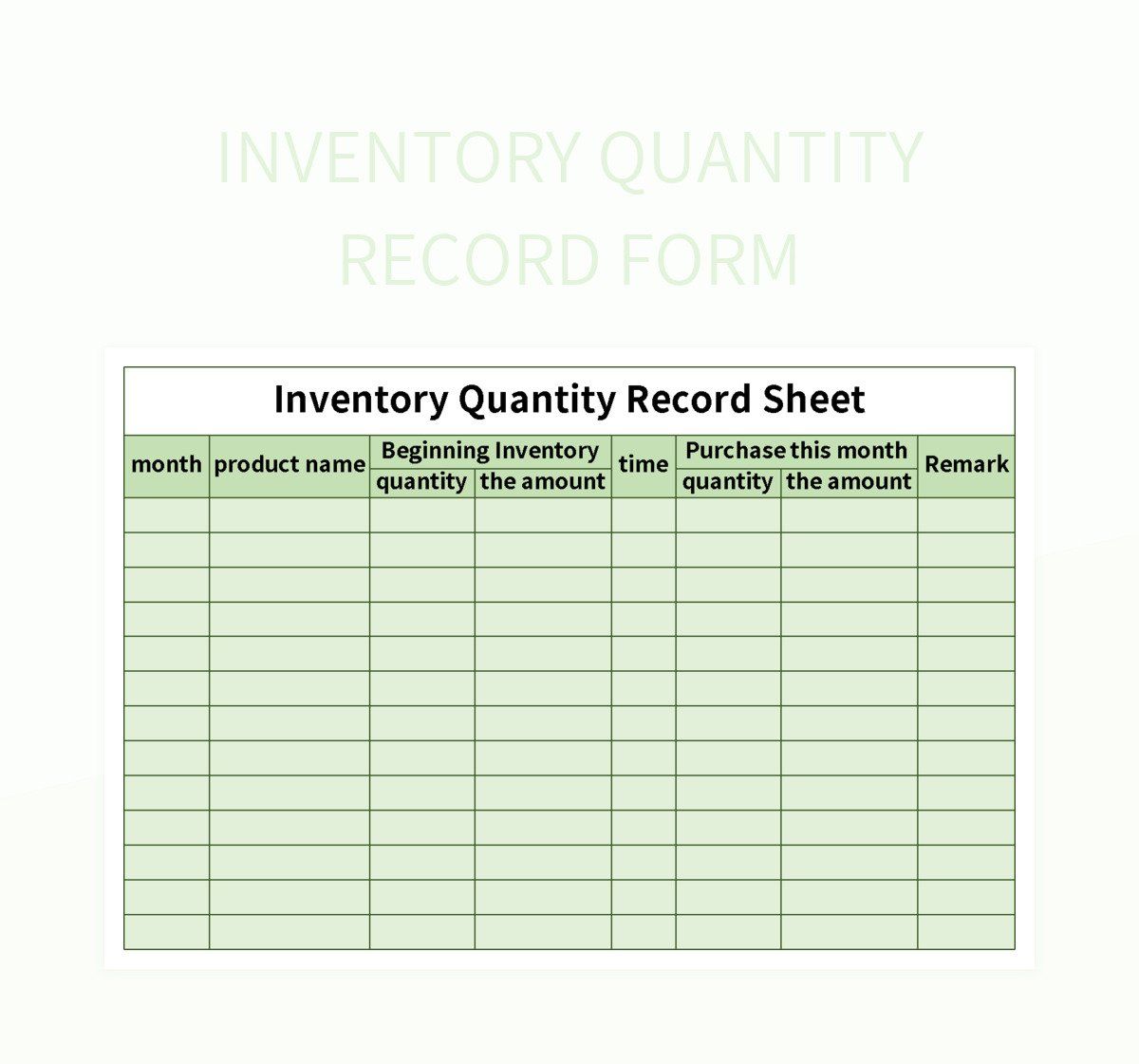

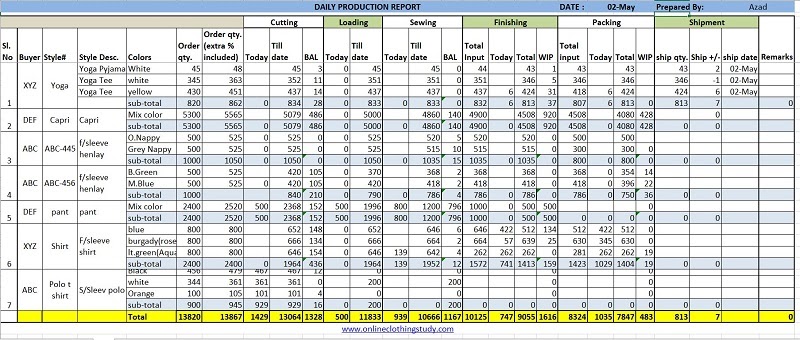

A material quantity record sheet is a document used to keep track of the quantity of different materials in stock. It typically includes columns for the material name, quantity on hand, quantity used, and remaining quantity. This sheet can be printed out and used manually to update the quantities as needed.

Having a record sheet like this can help you avoid running out of essential materials and streamline the inventory management process.

Why Use a Material Quantity Record Sheet?

There are several reasons why using a material quantity record sheet can be beneficial. Some of the key advantages include:

- Organized Inventory Management: By keeping track of material quantities in one centralized document, you can easily monitor stock levels and avoid shortages.

- Cost Savings: With an accurate record of materials on hand, you can optimize purchasing decisions and prevent overstocking.

- Time Efficiency: Having a record sheet saves time by providing a quick overview of materials available without the need for manual counting.

- Improved Planning: By knowing exactly how much of each material you have, you can plan production schedules or shopping lists more effectively.

How to Create a Material Quantity Record Sheet

Creating a material quantity record sheet is relatively simple and can be customized to fit your specific needs. Here are some steps to guide you through the process:

1. Start by listing all the materials you want to track on the sheet.

2. Create columns for material name, quantity on hand, quantity used, and remaining quantity.

3. Decide on the layout and design of the sheet, keeping it clear and easy to read.

4. Use a spreadsheet software like Microsoft Excel or Google Sheets to input your data and format the sheet.

5. Print out the completed record sheet for manual updating.

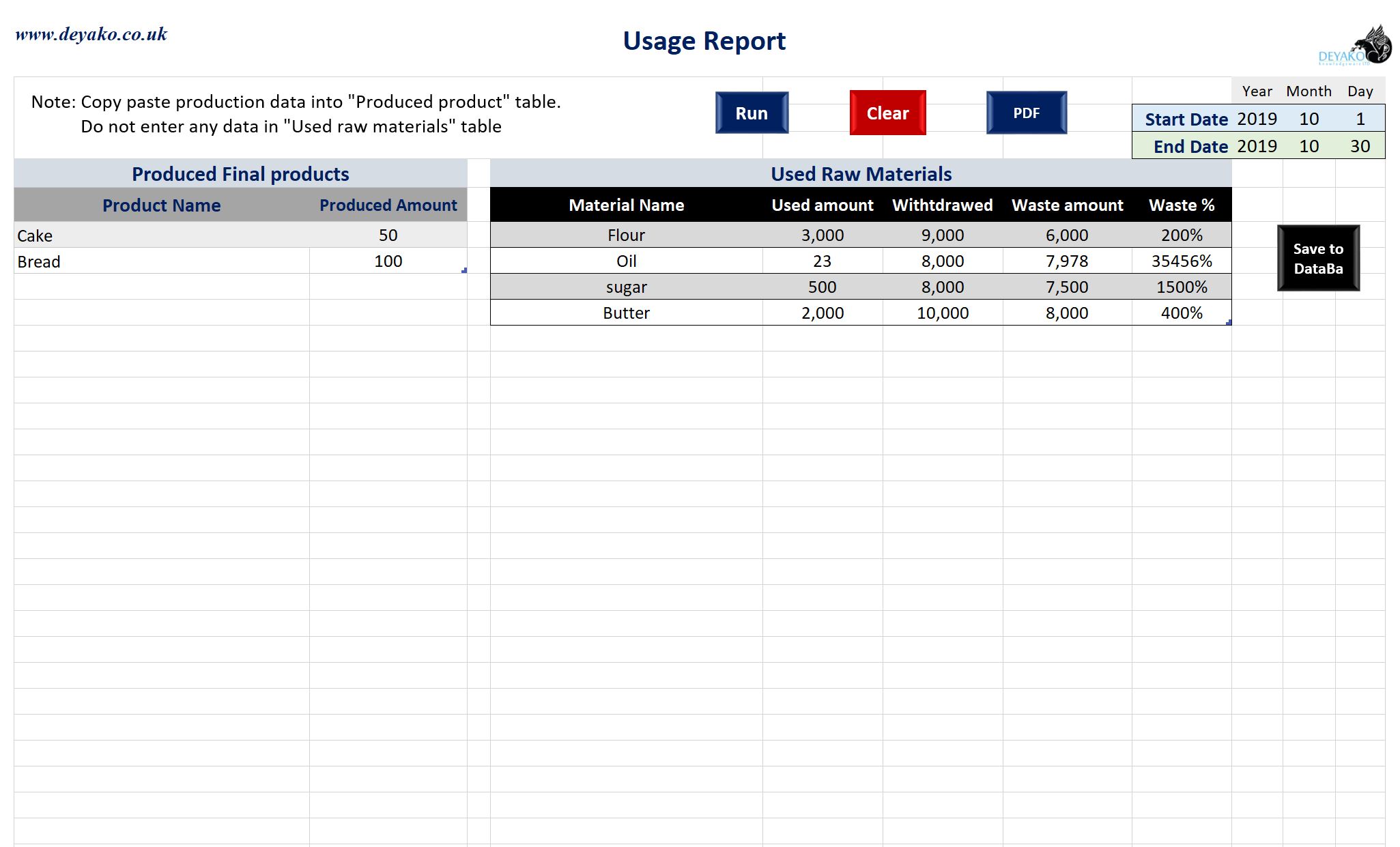

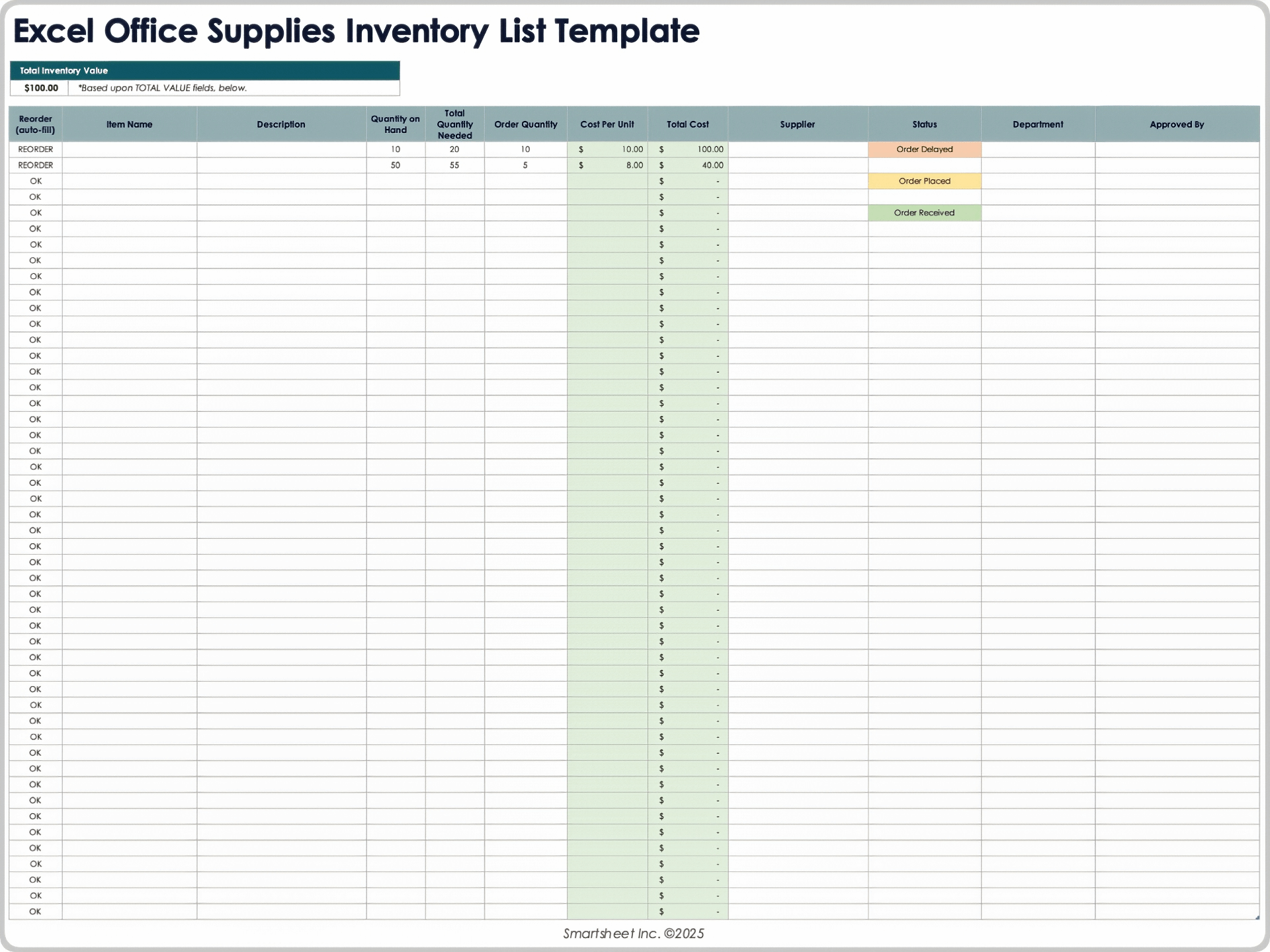

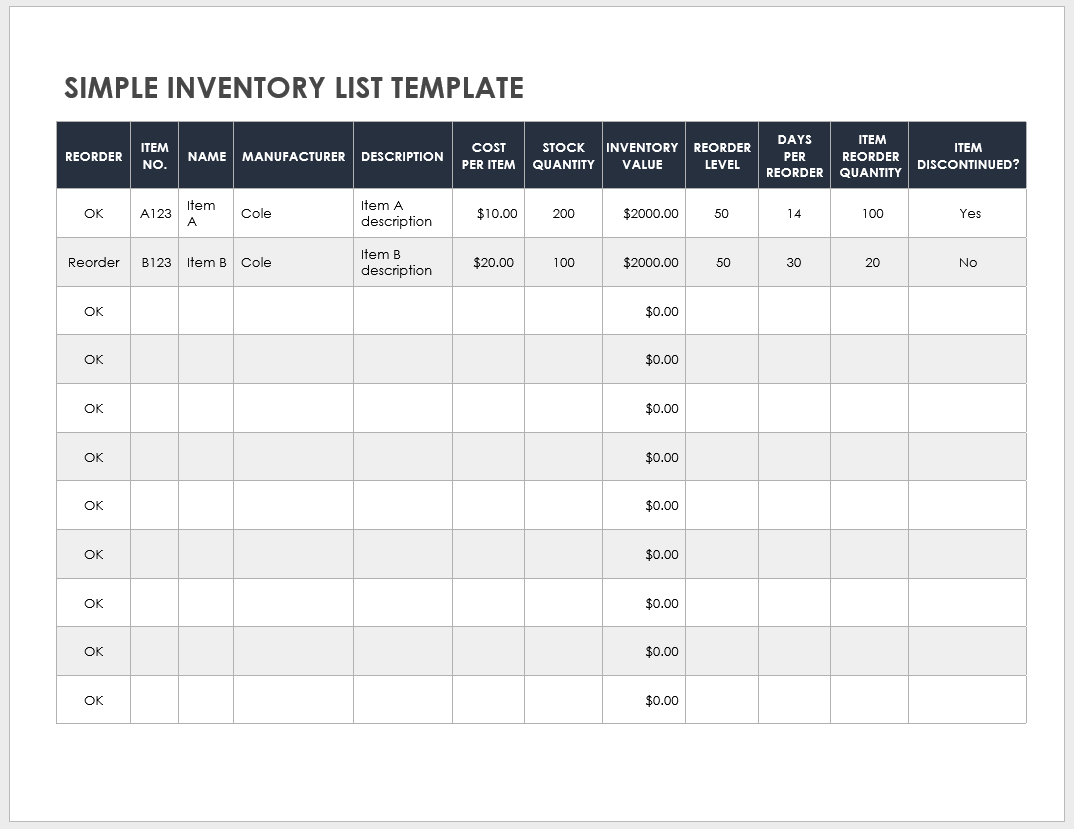

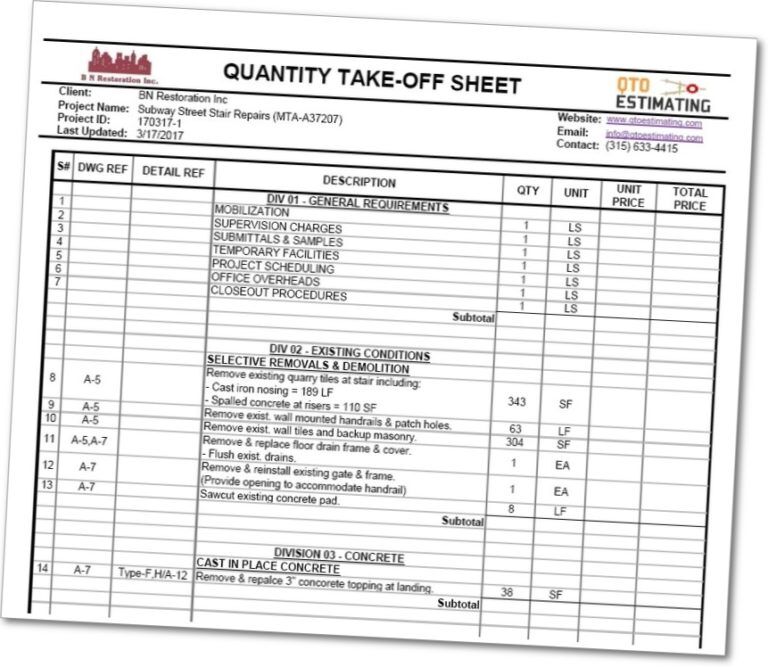

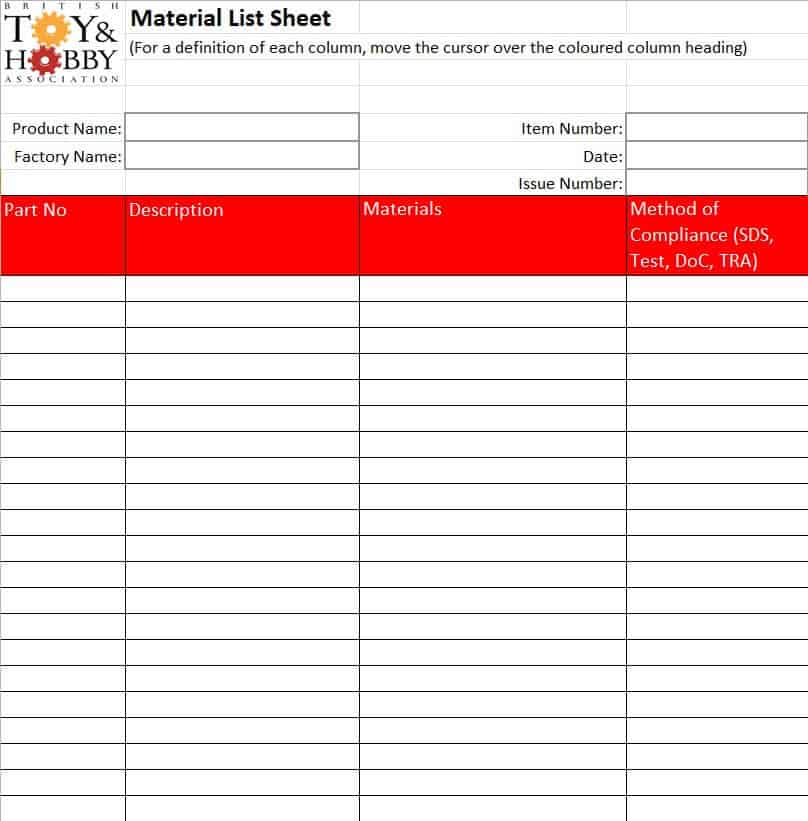

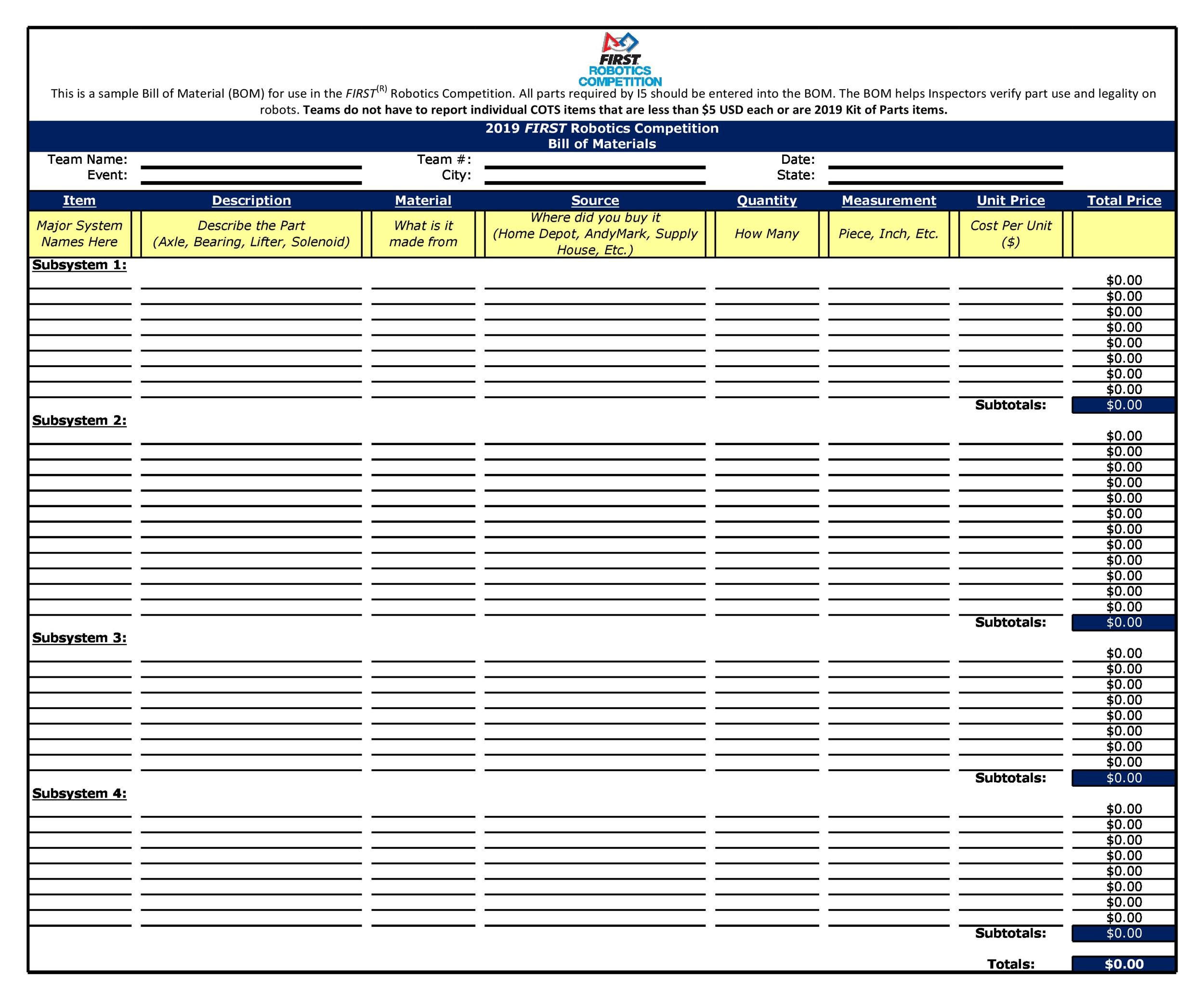

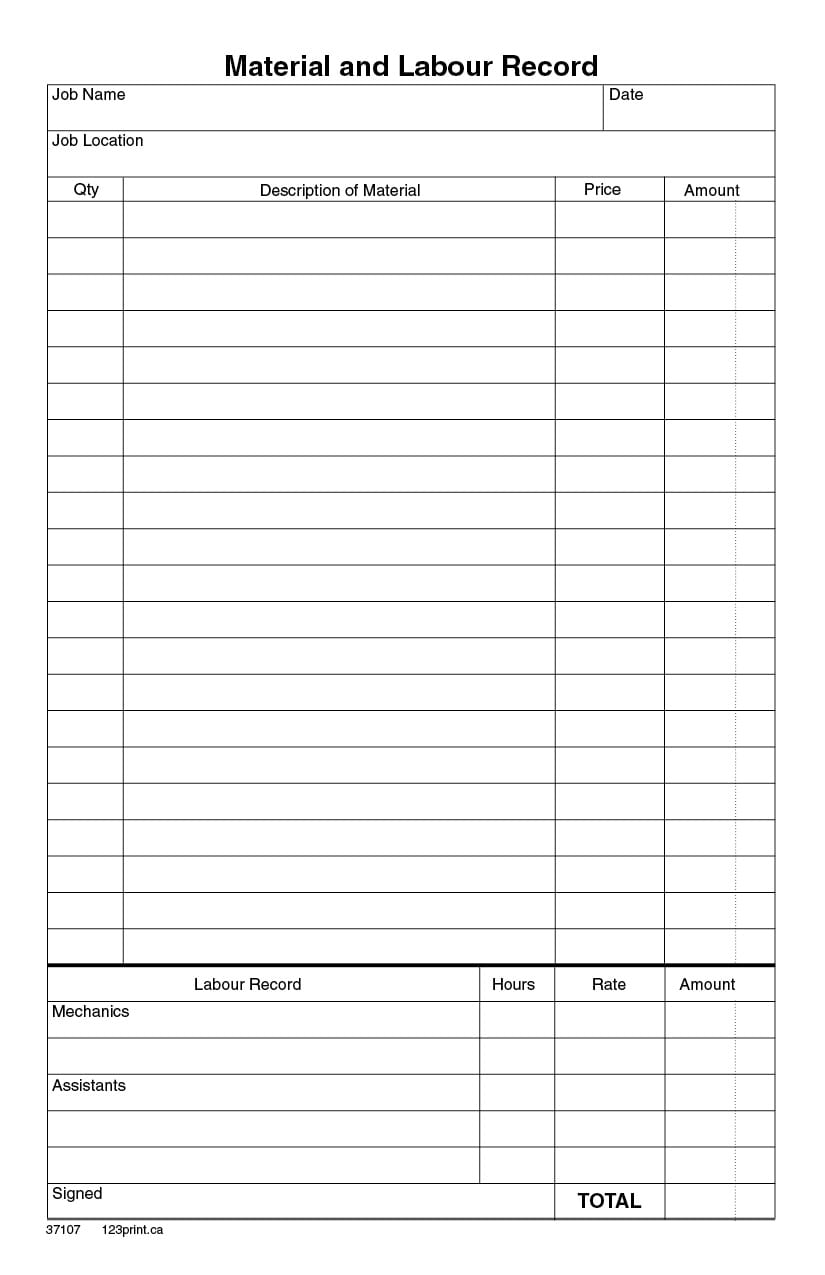

Examples of Material Quantity Record Sheets

To give you an idea of what a material quantity record sheet looks like, here are some examples:

Tips for Successful Implementation

To make the most out of your material quantity record sheet, consider the following tips:

- Regular Updates: Set aside time regularly to update the quantities on the sheet to ensure accuracy.

- Backup Copies: Keep digital copies of the record sheet in case of loss or damage to the physical copy.

- Labeling: Clearly label the sheet and keep it in a designated location for easy access.

- Training: If multiple people will be using the sheet, provide training on how to update and maintain it correctly.

- Review and Adjust: Periodically review the record sheet to identify any trends or areas for improvement in inventory management.

In conclusion, a material quantity record sheet is a valuable tool for efficient inventory management. By creating and using this document, you can streamline your stock control process, prevent shortages, and make informed decisions about material usage. Incorporate the tips provided in this guide to ensure successful implementation and maximize the benefits of utilizing a material quantity record sheet.

Material Quantity Record Sheet Template – Download